Step by step process from VCT/Mastic Removal to Decorative Broadcast Epoxy System.

Concrete Sealant

Sealing concrete is imperative for the preservation, protection and enhancement of all porous materials such as concrete. It helps prevent spalling, color loss, and pitting due to everyday wear and tear. Acrylic sealing is a quick and affordable application, which is ideal for any type of concrete including stamped, exposed aggregate and brick products. There are solvent based and water based sealers that come in a matte finish to a wet look high gloss. Ask NCR what would best suit your concrete maintenance needs. (Driveways, walkways, patio’s, garage pads & commercial/industrial warehouse concrete.)

Epoxy

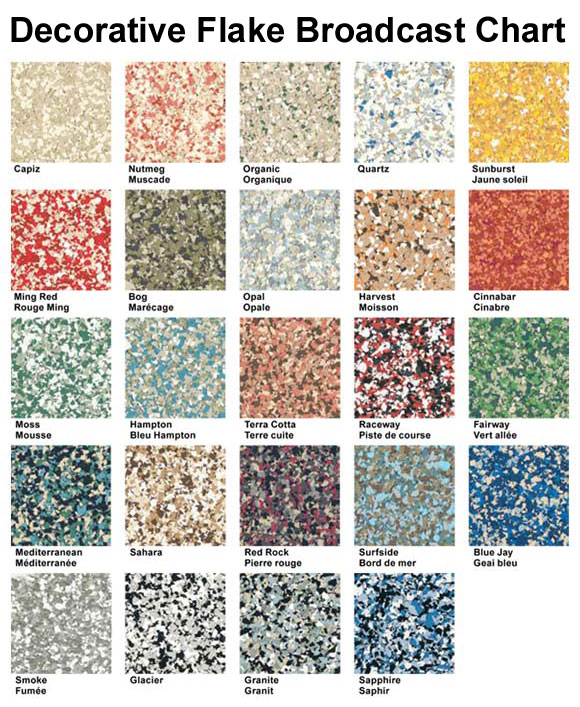

NCR uses self-levelling, re-coatable epoxies which are a two-component, heavy duty floor system that provides a high gloss, seamless, hygienic surface that is extremely hard wearing and durable while maintaining low VOC’s. The coating can also be applied to provide a non-slip texture. This product may be top coated if required. Epoxy coatings come in various base colours & quartz flake options and provide excellent oil/chemical resistance while drastically improving appearance and light reflectivity. Recommended Usage: Garages, Automotive Showrooms/Bays, Hospitals & Laboratories, Warehouses, Assembly Areas, Aircraft Hangars, etc…

Poly-Aspartic

Poly-aspartic coatings and sealers offer UV stability and non-yellowing compounds in solids and clears. Its characteristics allow it to cure in extreme temperatures(-30 Celsius), and in high humidity. Chemical resistance is excellent, extremely low VOC’s, and ready for next day service. Costs incurred by down time are dramatically reduced, making this system very feasible for retail, or commercial applications. Poly-Aspartic coatings and sealers can be used for flake, quartz, silica, and acid stain applications. Recommended Usage: Garages, Automotive Showrooms/Bays, Hospitals & Laboratories, Warehouses, Assembly Areas, Aircraft Hangars, etc…

Densifier

Concrete densifier and chemical hardener, hardens and dustproofs concrete at a molecular level. A densified, finished surface offers substantial improvement in abrasion and chemical resistance and will significantly improve the durability of the surface when compared to untreated concrete. As the densifier penetrates into the concrete surface, a chemical reaction occurs with the free lime and calcium, producing a by-product that fills the pores of the concrete. This in turn creates a substantially denser concrete surface with enhanced durability. This system is proven to eliminate dusting and pitting of the concrete. After the densification process, a concrete enhancer can then be applied to produce a high level of sheen that greatly increases appearance and light reflectivity. This environmentally safe, water-based product features a zero VOC content and provides an attractive option in green building applications. Recommended Usage: Industrial Plants and Warehouses, Storage Silos, Sewage Plants, Chemical Processing Facilities, Refineries, and Heavy Pedestrian Floor Traffic Areas, such as Civic Centers, Sports Arenas, Stadiums, Hospitals, Airports, and Museums.